Robotics is fast moving past the stage of gimmicks and is soon to become part of normal life, as it grows far beyond Sony's beloved Aibo robotic dog and the Roomba robotic vacuum cleaner.

Nowadays, a basic understanding of robotics and an Internet connection allow anyone to explore the diverse world of the Internet of things (IOT), and come up with inventive solutions to everyday problems.

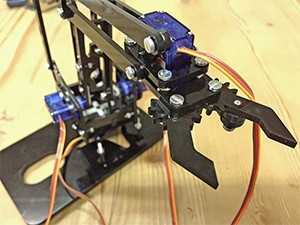

This is reflected in the thinking behind the eeArm, a robotic arm measuring less than 20cm tall.

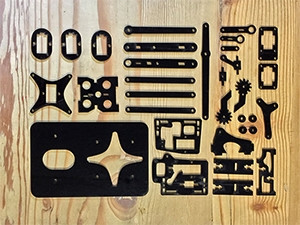

The eeArm is made up of an easy-to-assemble kit, consisting of a variation of laser-cut parts (these can be Perspex, wood or any other thin, hard material), nuts and screws, and servo gear. Everything in the kit is open source.

The kit lowers the barrier to entry to hobbyist IOT, say its creators.

From fish to coffee

A team of software developers and 'makers' from Durban developed the 'arm' that can be connected to a local WiFi network - meaning it can be controlled from anywhere in the world over an Internet connection.

"For example, you could press a button on your phone before getting out of bed in the morning and your eeArm robot could flick your kettle on. By the same token, you could get it to feed your fish from half the world away."

Once the robot is set up, parts are interchangeable, depending on how finicky or complex the required action will be.

"Once you have a connected device that can realise actions in the physical world, the possibilities are essentially boundless," said the team in an interview at gaming expo rAge this past weekend.

The team consists of Chris Fraser (hardware, firmware and app development), Steve Gray (mechanical engineering), Taylor Gibb (app development), and Peter Edwards as team lead.

The project is still in its infancy, but the team hopes to raise money through a Kickstarter campaign to make the kits available to more people.

"We believe that a robot arm is a fantastic way to bridge the intangible world of software with the physical world."

The team said the aim of the project is twofold: "We would like to produce an affordable platform that hobbyists can use for almost any IOT project. And, after testing a number of open source robot arms, feel there is room for improvement."

The current mechanical design is based on the open source robotics and coding starter kit, MeArm, with the ESP8266 chip.

"This ESP chip is a very low-cost WiFi-enabled microcontroller that has come out of China. It has features similar to that of an Arduino, with integrated WiFi. The current version of the firmware is programmed using the normal Arduino environment, with the addition of a few bridging libraries," said Fraser.

Mysterious chip

Gibb explained the term Arduino is complicated at the moment as it refers to both a programming language and associated electronics boards created by a university group in Italy.

"The firmware for the ESP8266 is written in the Arduino language using some additional tools created by the open source community.

"The ESP8266 chip sort of mysteriously appeared out of China, so it doesn't have the same level of documentation and support as Arduino but there are plenty of enthusiasts solving this problem," said GIbb.

"The chip is really cheap and powerful, but kind of useless on its own. There is big impetus in the [open source and maker] community to create tooling around the ESP8266 so that everyone can use it.

"We have created a breakout board for the ESP chip so there is no need for soldering, and installed firmware to allow it to run Arduino language, so people familiar with Arduino can plug-and-play."

The eeArm is differentiated from other robotic kits because of its integrated WiFi 'brain'. "It runs Arduino code and can connect as a client or host and control an array of I/Os [input/outputs]. It's basically a cheap, powerful, programmable IOT platform. We built it with the robot arm in mind, but it can do lots more."

The robotic arm was first showcased at the Fak'ugezi Market Hack in Johannesburg last month.

This project was partially self-funded by team members, but there were a number of sponsors. Durban-based software development firm Derivco (which Fraser, Gibb and Edwards work for) contributed towards the material cost of the first batch of robotic arms. The British Council was another key sponsor.

'Makers' is a term used to describe people who use open technology platforms to create their own devices. In Durban, there is an established Maker Space that offers members access to 3D printers, laser cutters, and offers a range of handmade and electronic courses.

To get involved in this project or to follow its progress, people are able to connect with the team on their Web site. Those interested (and based in Durban) are also encouraged to visit the MakerSpace on a Tuesday night, when the team and local maker community meet.

Share